ASPHALTIC EMULSION FOR PRIMING (EIP)

The asphalt emulsion for slow breaking type priming is an emulsion with a lower viscosity and the size of the particles that compose it is up to 4 times smaller than that of a conventional emulsion, which guarantees the necessary penetration to fulfill the functions of a primer.

- Application at ambient temperature.

- Asphalt residue between 40 - 50%.

- Increases the surface cohesion of the base.

- Waterproofs this layer during road construction.

- Generates adhesion between the base and the bituminous material layer to be placed on top.

- Transit release between 12 to 24 hours*.

(*) The release time of the traffic on the primed base will be within 12 to 24 hours after its application, depending on the climatic conditions. The application is not recommended in case of imminent rain.

EIP is designed to be applied at room temperature to avoid thermal shock with the base. If pre-heating is necessary, it is recommended not to exceed 45 degrees. In case of long term storage, it is recommended to recirculate prior to application.

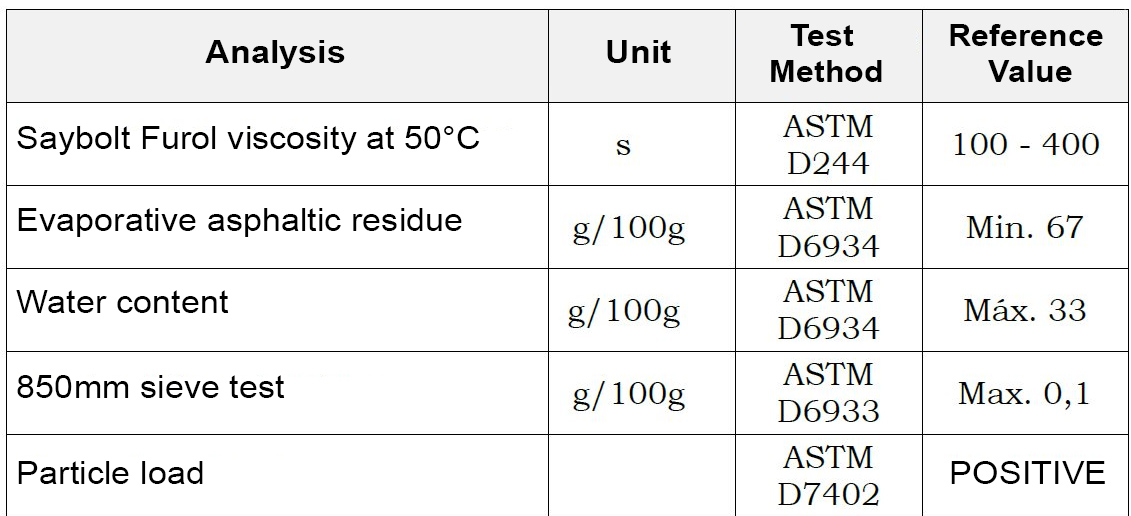

Technical specifications

SLOW BREAKING CATIONIC ASPHALTIC ASPHALTIC EMULSION (RL1C)

- 60% asphalt residue.

- Application at ambient temperature.

- Designed to give maximum mixing stability.

- It has long periods of workability.

- It presents low viscosities.

RL1C is designed to be applied at room temperature to avoid thermal shock with the base. In case of long term storage, it is recommended to recirculate the product once a week and/or before application. Do not store diluted emulsions.

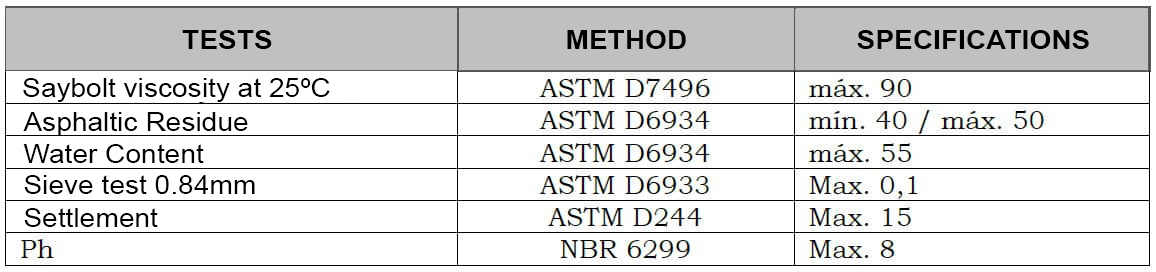

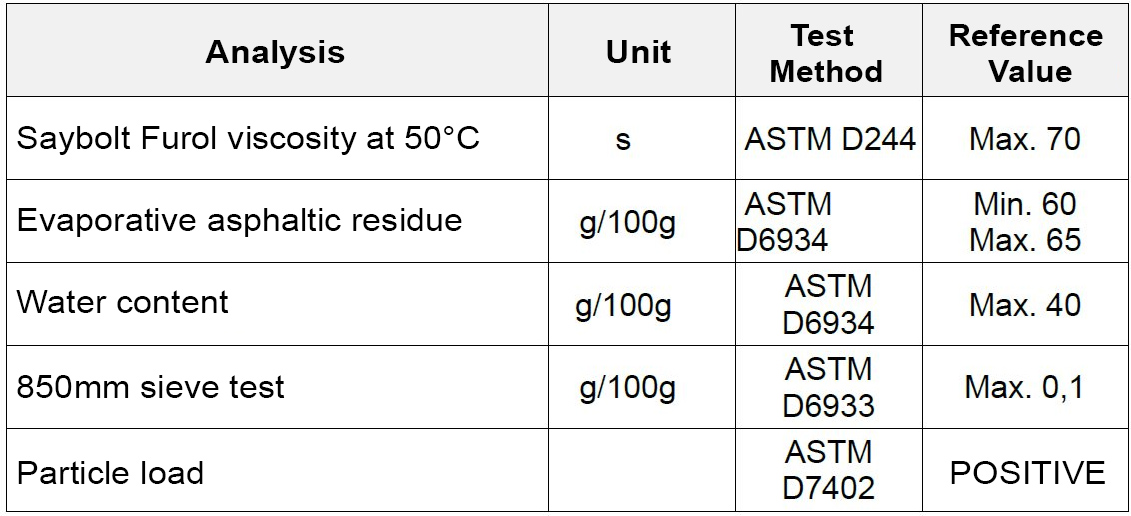

Technical specifications

MEDIUM BREAKING ASPHALTIC EMULSION - RM1C

These emulsions are designed to be mixed with coarse aggregates and do not break immediately upon contact with the aggregate. They are used when more time is needed to work the mixes.

The emulsion should not be heated above 60°C, as this may cause it to break. It should not be stored in tanks containing residues of other products. Storage for prolonged periods is also not recommended, being necessary to recirculate every week and/or before the application of the product, always avoiding the formation of foam and overheating.

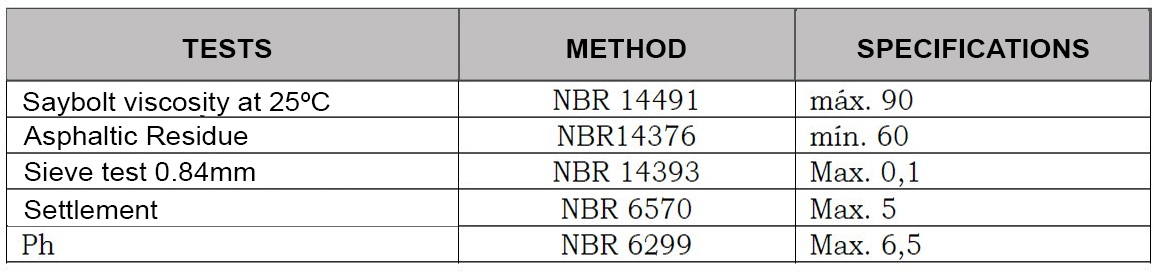

Technical specifications

CATIONIC FAST BREAKING ASPHALTIC EMULSION - RR1C

The maximum temperature for heating the product is 50 degrees. Only the amount of product to be used should be heated and, above all, overheating should be avoided.

The stagnant product inside the storage tank must be recirculated every 5 days, not heated, to maintain its quality.

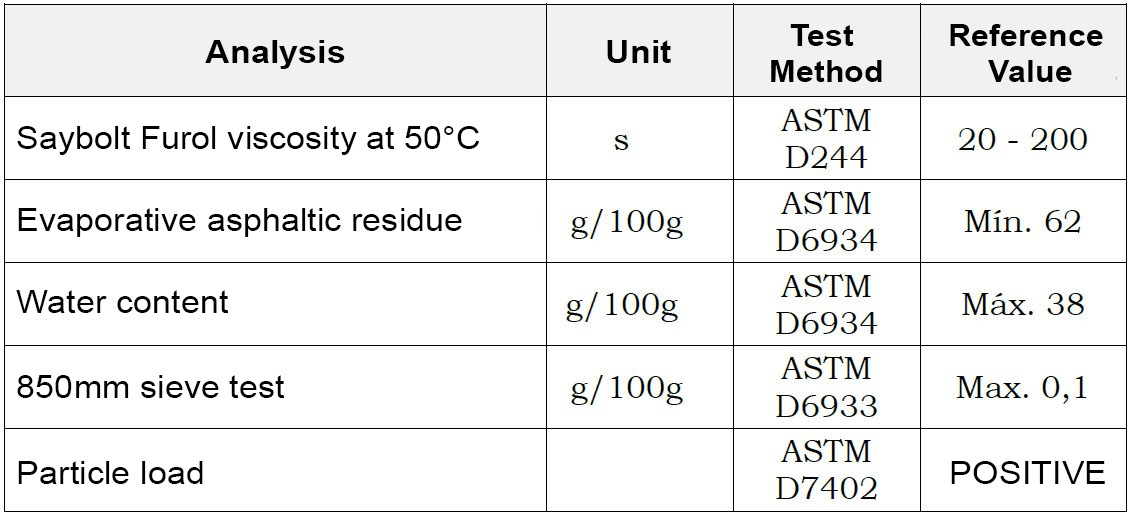

Technical specifications

CATIONIC FAST-BREAKING ASPHALTIC EMULSION TYPE 2- RR2C

To obtain the right viscosity conditions for spreading, the emulsion temperature should be 65°C, with a maximum limit of 70°C, already in the spraying vehicle. Only the quantity of product to be used should be heated and, above all, overheating should be avoided as it could cause irreversible changes in its characteristics. It is not recommended to store the product for more than 20 days, being necessary to recirculate it before its application.

Technical specifications